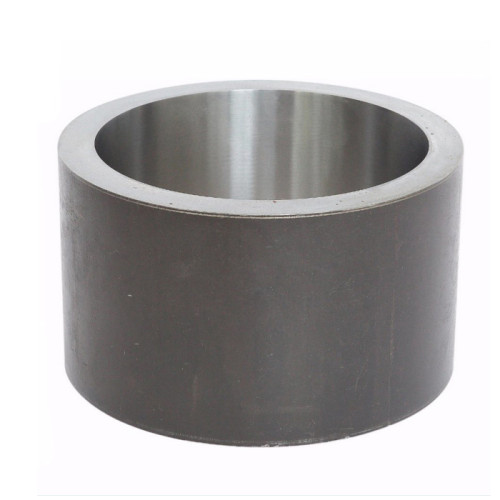

27SiMn SRB Honed Tube

- Model

- No Model

Review

Description

27SiMn Tempered &Hardened Honed Tube

High Material Grade

C20 CK45 ST52 25Mn 27SiMn Seamless steel

Well Mechanical Properties

Tensile strength>600 N/mm² Yield strength>520 N/mm² Elongation>15% Hardness>200HB

Wide-range spec

OD: 40--500 mm ID:25--400 mm Wall thickness: 3--50 mm Length: 30--8000 mm

High precision

Straightness<0.2 mm/1000mm Roughness Ra<0.2 um Tolerance: H8

International Standard & Certificate

API ASTM BS DIN EN GB JIS

ISO9001 TS16949

1. Price: FOB Shanghai or CIF & CFR Price.

2. Delivery time: within 30 days.

3. Packing: Plastic cloth pakage with Bundle. Both end caps.

4. Marking: on request.

5. Mill MTC: Certificate stamped by Mill’s inspection Authority.

6. Payment: 30% advance and balance again BL copy.

7. Negotaiable Documents: One set of commercial Invoice, Packing list. Bill of Lading, Mill Test Certificate. CO.

8. Trade Assurance order is welcomed.Chemical Composition

Technique and tolerance:

Technique and tolerance: